Understanding the Importance of Simple Cycle Turbine Repair and Maintenance

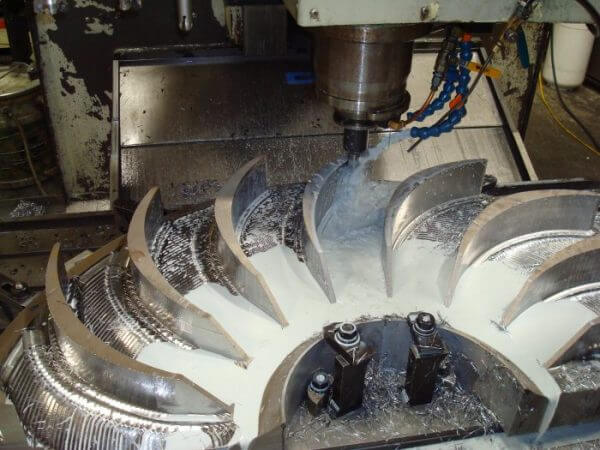

Simple cycle turbines are vital components in various industries such as energy production, manufacturing, and aviation. These turbines are used to generate electricity, power machinery, and propel aircraft, making them essential for the functioning of modern society. To ensure the efficient operation and longevity of simple cycle turbines, it is crucial to prioritize repair and maintenance activities.

Importance of Regular Maintenance

Regular maintenance of simple cycle turbine repair is essential to prevent costly breakdowns and ensure optimal performance. By conducting routine inspections and servicing, potential issues can be identified and addressed before they escalate into major problems. Maintenance tasks such as cleaning, lubrication, and parts replacement help to keep the turbine running smoothly and efficiently.

Enhancing Safety

Proper repair and maintenance of simple cycle turbines are not only important for operational efficiency but also for safety. Malfunctioning turbines can pose serious safety risks to personnel working near the equipment. Regular maintenance helps to mitigate these risks by keeping the turbine in good working condition and reducing the likelihood of accidents.

Furthermore, routine inspections and repairs can also extend the lifespan of the turbine and prevent costly breakdowns. By following manufacturer recommendations and scheduling regular maintenance checks, operators can ensure that their simple cycle turbines are operating safely and efficiently. Effective maintenance practices also contribute to overall improved performance and output of the turbine, ultimately leading to better operational results for the facility.

Increasing Longevity

Effective repair and maintenance practices can significantly extend the lifespan of simple cycle turbines. By addressing issues promptly and implementing preventive maintenance measures, the overall durability and reliability of the turbine can be enhanced. This not only saves costs associated with frequent repairs but also maximizes the return on investment in the equipment.

Regular inspection of the turbine components such as the combustion chamber, compressor, and turbine blades is crucial to identify potential problems early on. Cleaning and lubricating moving parts, as well as testing and replacing worn-out parts, are important steps in ensuring optimal performance.

In addition, following the manufacturer’s guidelines for maintenance schedules and using high-quality parts for repairs can further improve the efficiency and longevity of the turbine. Training personnel on proper maintenance practices and safety protocols is also essential to prevent accidents and ensure smooth operations.

By investing time and resources in proactive maintenance strategies, operators can not only extend the lifespan of simple cycle turbines but also minimize downtime and maintain consistent performance levels. Ultimately, effective repair and maintenance practices play a key role in maximizing the overall efficiency and profitability of turbine operations.

Improving Efficiency

Well-maintained simple cycle turbines operate more efficiently, consuming less fuel and producing higher output. Regular servicing helps to optimize the performance of the turbine, ensuring that it delivers the expected power output with minimal energy wastage. This improved efficiency translates to cost savings and environmental benefits.

Regular servicing and maintenance play a crucial role in ensuring that simple cycle turbines operate efficiently. By keeping the turbines well-maintained, they can consume less fuel and produce a higher output, ultimately leading to cost savings and environmental benefits.

Optimizing the performance of the turbines through servicing not only helps in maximizing power output but also minimizes energy wastage. This improved efficiency is not only economical but also contributes to reducing the carbon footprint and promoting a more sustainable energy generation process.

Reducing Downtime

Unexpected breakdowns of simple cycle turbines can lead to costly downtime for industries relying on these machines for their operations. Planned maintenance activities help to minimize the risk of unscheduled outages by keeping the turbine in good condition. Scheduled repairs and inspections can be carried out during off-peak periods to reduce disruptions to productivity.

Compliance with Regulations

Certain industries are subject to regulatory requirements regarding the maintenance of equipment such as simple cycle turbines. Adhering to these regulations is essential to ensure compliance and avoid penalties. By maintaining detailed records of repair and maintenance activities, businesses can demonstrate their commitment to upholding industry standards and best practices.

Specialized Expertise

Repairing and maintaining simple cycle turbines requires specialized knowledge and skills that are best handled by trained professionals. Hiring experienced technicians or engaging with authorized service providers ensures that the work is carried out to high standards. These experts have the necessary training and equipment to diagnose issues accurately and perform repairs effectively.

Cost-Effectiveness

While investing in repair and maintenance may incur upfront costs, it is a cost-effective strategy in the long run. Regular servicing helps to identify minor issues early on, preventing them from developing into major faults that require expensive repairs. Additionally, well-maintained turbines are more energy-efficient, resulting in lower operational costs over time.

Conclusion

The importance of simple cycle turbine repair and maintenance cannot be overstated. By prioritizing regular servicing, businesses can enhance the safety, longevity, efficiency, and reliability of their turbines while minimizing downtime and ensuring compliance with regulations. Investing in professional repair and maintenance services not only protects equipment investment but also contributes to overall operational excellence and cost savings.